-

όργανα δοκιμής πετρελαίου

-

Όργανα δοκιμής αντιψυκτικού λαδώνοντας πετρελαίου και λιπών

-

Εξοπλισμός δοκιμής καυσίμων diesel

-

Εξοπλισμός δοκιμής πετρελαίου μετασχηματιστών

-

Όργανο δοκιμής τροφών

-

Φαρμακευτικά όργανα δοκιμής

-

Εξοπλισμός δοκιμής λαδιού

-

Χημικά όργανα ανάλυσης

-

Εξοπλισμός δοκιμής πετρελαίου λιπαντικού ελαίου

-

Όργανο δοκιμής αλευριού

-

Όργανα δοκιμής τροφίμων

-

Εξοπλισμός δοκιμής αργού πετρελαίου

-

Υδραυλικός εξοπλισμός δοκιμής πετρελαίου

-

Ελεγκτής σημείου ανάφλεξης

-

Κινηματικός ελεγκτής ιξώδους

-

Ελεγκτής σημείου ψύξης

-

Συσκευές διείσδυσης κώνων

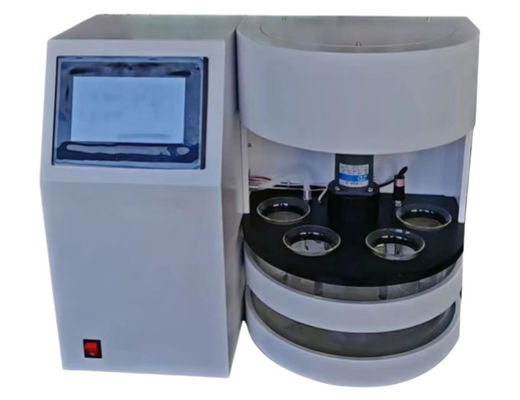

SH123 Αυτόματος Ελεγκτής Διάβρωσης Υγρής Φάσης 4 Δειγμάτων Αισθητήρας PT100 ASTM D665

Με ελάτε σε επαφή με δωρεάν δείγματα και δελτία.

WhatsApp:0086 18588475571

wechat: 0086 18588475571

Skype: sales10@aixton.com

Εάν έχετε οποιαδήποτε ανησυχία, παρέχουμε τη 24ωρη σε απευθείας σύνδεση βοήθεια.

x| Temp ακρίβεια ελέγχου | ± 0,1 ℃ | Πεδίο ελέγχου θερμοκρασίας | Θερμοκρασία δωματίου 100 °C |

|---|---|---|---|

| Στοιχείο μέτρησης θερμοκρασίας | αντίσταση λευκόχρυσου (PT100) | Ποσότητα δειγμάτων | 4 |

| Χρόνος ελέγχου θερμοκρασίας | 0-100 ώρες | Μέγεθος | 500 * 330 * 750 mm |

| Βάρος | Περίπου 25 κιλά | Περιβαλλοντική θερμοκρασία | 0 ℃ ~ 45 ℃ |

| Επισημαίνω | Αυτόματος Δοκιμαστής Διάβρωσης σε Υγρή Φάση,Αυτόματος Δοκιμαστής Διάβρωσης σε Υγρή Φάση,Δοκιμαστής Διάβρωσης σε Υγρή Φάση για 4 Δείγματα |

||

SH123 Αυτόματος Ελεγκτής Διάβρωσης Υγρής Φάσης

Ο αυτόματος ελεγκτής διάβρωσης υγρής φάσης SH123 έχει σχεδιαστεί και κατασκευαστεί αυστηρά σύμφωνα με τα πρότυπα GB/T11143 "Μέθοδος Δοκιμής για την Απόδοση Αντισκωριακής Προστασίας Ορυκτελαίων με Αναστολείς παρουσία νερού" και GB/T 19230.1 "Μέθοδος Δοκιμής για την Απόδοση Αντισκωριακής Προστασίας Καθαριστικών Βενζίνης". Χρησιμοποιείται κυρίως για την αξιολόγηση της απόδοσης αντισκωριακής προστασίας ορυκτελαίων με αναστολείς και ελαίων στροβίλων σε σιδηρούχα εξαρτήματα όταν αναμειγνύονται με νερό. Το ίδιο ισχύει και για τον προσδιορισμό της απόδοσης αντισκωριακής προστασίας υδραυλικών ελαίων και ελαίων κυκλοφορίας. Ο ελεγκτής διάβρωσης υγρής φάσης μπορεί να χρησιμοποιηθεί ευρέως σε τμήματα όπως η ενέργεια, το πετρέλαιο, η χημική βιομηχανία, η εμπορική επιθεώρηση και η επιστημονική έρευνα.

Το πρότυπο GB/T11143 ASTM D665 είναι εφαρμόσιμο για τον προσδιορισμό της αντοχής στη διάβρωση λιπαντικών ελαίων, υδραυλικών ελαίων, ελαίων στροβίλων και άλλων ελαίων σε μέταλλα όταν περιέχουν νερό και για την αξιολόγηση της απόδοσης αντιδιαβρωτικών προσθέτων.

Κύριες τεχνικές παράμετροι και χαρακτηριστικά

| Μέθοδος ελέγχου θερμοκρασίας | Ψηφιακή οθόνη LCD |

| Ακρίβεια ελέγχου θερμοκρασίας | ± 0.1 ℃ |

| Εύρος ελέγχου θερμοκρασίας | Θερμοκρασία δωματίου ~ 100 ℃ |

| Αναμείξη δείγματος | 1000 ± 50 στροφές ανά λεπτό |

| Στοιχείο μέτρησης θερμοκρασίας | Αντίσταση πλατίνας (PT100) |

| Λειτουργία ενυδάτωσης | λειτουργία αυτόματης αναπλήρωσης |

| Ποσότητα δείγματος | 4 |

| Χρόνος ελέγχου θερμοκρασίας | 0-100 ώρες |

| Θερμοκρασία περιβάλλοντος | 0 ℃ ~ 45 ℃ |

| Υγρασία περιβάλλοντος | ≤ 85% |

| Τροφοδοσία | AC220V/50Hz |

| Διαστάσεις | 500 * 330 * 750mm |

| Βάρος | Περίπου 25kg |

![]()

● Υιοθετεί οθόνη μεγάλης οθόνης LCD μπλε χρώματος, κινέζικο μενού και μη επισημασμένα κουμπιά. Αυτόματος έλεγχος θερμοκρασίας μικροϋπολογιστή, αυτόματος χρονισμός, διαισθητική και απλή λειτουργία. Τέσσερις κινητήρες χρησιμοποιούνται για ξεχωριστή ανάμειξη, χωρίς θόρυβο, ασφάλεια και αξιοπιστία και συμπαγές μέγεθος. Μπορεί να καλύψει τις ανάγκες των διυλιστηρίων πετρελαίου, των σταθμών παραγωγής ενέργειας και των ερευνητικών ιδρυμάτων και είναι ένα από τα απαραίτητα όργανα για την ανάλυση πετρελαίου και τον ποιοτικό έλεγχο

● Μέθοδος ελέγχου θερμοκρασίας: Ψηφιακή οθόνη LCD

● Ακρίβεια ελέγχου θερμοκρασίας: ± 0.1 ℃

● Εύρος ελέγχου θερμοκρασίας: Θερμοκρασία δωματίου ~ 100 ℃

● Αναμείξη δείγματος: 1000 ± 50 στροφές ανά λεπτό

● Στοιχείο μέτρησης θερμοκρασίας: Αντίσταση πλατίνας (PT100)

● Λειτουργία ενυδάτωσης: με λειτουργία αυτόματης αναπλήρωσης

● Ποσότητα δείγματος: 4 ομάδες και μπορούν να γίνουν 4 δείγματα ταυτόχρονα. ● Μπορείτε επίσης να επιλέξετε να ανοίξετε οποιαδήποτε ομάδα πειραμάτων ανάλογα με την κατάστασή σας, χωρίς να παρεμβαίνετε μεταξύ τους

● Χρόνος ελέγχου θερμοκρασίας: ελεύθερα ρυθμιζόμενος από 0 έως 100 ώρες

● Θερμοκρασία περιβάλλοντος: 0 ℃ ~ 45 ℃

● Υγρασία περιβάλλοντος: ≤ 85%

● Τροφοδοσία: AC220V/50Hz

● Διαστάσεις: 500 × 330 × 750mm

● Βάρος: Περίπου 25kg

Απαιτούμενα αναλώσιμα: διαλυτικά πλύσης. Τα φύλλα χαλκού και οι ράβδοι χάλυβα δοκιμής είναι εξοπλισμένα με τα δικά τους όργανα και μπορούν να αγοραστούν ή να παρασχεθούν από τον χρήστη μετά τη χρήση.

Σημείωση:Οι εικόνες εμφάνισης, οι διαστάσεις, ο όγκος και το βάρος του οργάνου είναι μόνο για αναφορά. Εάν υπάρχουν ενημερώσεις στο όργανο, ενδέχεται να υπάρξουν μικρές αλλαγές χωρίς προηγούμενη ειδοποίηση.

Η Shandong Shengtai Instrument Co., Ltd. παρέχει την ακόλουθη διασφάλιση ποιότητας για τα όργανα που σας πωλούνται:

----Τα παρεχόμενα υλικά οργάνων είναι ολοκαίνουργια, πληρούν τα εθνικά πρότυπα ποιότητας και διαθέτουν πιστοποιητικό συμμόρφωσης του κατασκευαστή;

----Τα υλικά και τα κύρια εξαρτήματα που παρέχονται πληρούν τις τεχνικές απαιτήσεις που καθορίζονται στην τεχνική τεκμηρίωση;

----Η συνολική περίοδος διασφάλισης ποιότητας του εξοπλισμού είναι ένα έτος (εξαιρουμένης της κανονικής φθοράς των ευάλωτων εξαρτημάτων).

----Είμαστε υπεύθυνοι για τη δωρεάν συντήρηση τυχόν προβλημάτων ποιότητας οργάνων που προκύπτουν κατά τη διάρκεια της περιόδου εγγύησης. Λόγω δυσλειτουργίας του εξοπλισμού που προκαλείται από την ευθύνη του χρήστη, είμαστε υπεύθυνοι για την επισκευή και τη χρέωση εύλογων τελών.

----Δια βίου μειωμένη προμήθεια ανταλλακτικών για εξοπλισμό και δια βίου συντήρηση και επισκευή ολόκληρης της μηχανής.

----Μετά τη λήξη της περιόδου εγγύησης, εάν ο χρήστης χρειάζεται συντήρηση και τεχνικές υπηρεσίες, θα χρεώσουμε μόνο ένα κόστος.

![]()

Λίστα συσκευασίας

| Αριθμός | Όνομα | Ποσότητα | Μονάδα | Σημείωση |

| 1 | Κεντρική μονάδα | 1 | Μονάδα | |

| 2 | Ποτήρι ζέσεως | 4 | Τεμάχιο | |

| 3 | Καπάκι ποτηριού ζέσεως | 4 | Τεμάχιο | |

| 4 | Ράβδος χάλυβα πειράματος | 4 | Τεμάχιο | |

| 5 | Η ράβδος ανάδευσης | 4 | Τεμάχιο | |

| 6 | Γάζα οξειδίου του αργιλίου | 4 | Τεμάχιο | |

| 7 | Γραμμή ρεύματος | 1 | Λωρίδα | |

| 8 | Σωλήνας ασφάλειας | 1 | Τεμάχιο | |

| 9 | Οδηγίες λειτουργίας | 1 | Αντίγραφο | |

| 10 | Λίστα συσκευασίας | 1 | Αντίγραφο | |

| 11 | Πιστοποιητικό συμμόρφωσης | 1 | Αντίγραφο |